Why Energy-Efficient Motors Matter for Your Bottom-Line

Industrial businesses, manufacturers, and facility managers are under increasing pressure to cut costs and reduce their environmental footprint. In today's competitive market, upgrading to energy-efficient motors is a practical step toward achieving both. These motors use less electricity, lower operational expenses, and help you meet new sustainability and regulatory standards. Here’s why you should make the switch:

Lower Costs and Faster Returns

Energy-efficient motors consume less electricity than older models. This reduction in energy use means lower electricity bills and quicker payback on your investment. Many businesses are choosing energy-efficient motors because they provide a faster return on investment (ROI). As a bonus, there are also many government incentives and rebates available that can help reduce the initial cost of upgrading your equipment.

Reducing Environmental Impact

Switching to energy-efficient motors not only saves money but also reduces your company’s carbon footprint. By using less energy, your business can lower greenhouse gas emissions and support sustainability goals. This is important as new regulations and environmental standards continue to emerge.

Government Incentives

There are several rebate programs and incentives available from the Government of Canada and local agencies. These programs help offset the cost of upgrading your motors, making it easier to invest in energy-efficient technology. Our team can help you navigate these options and choose the best solution for your business.

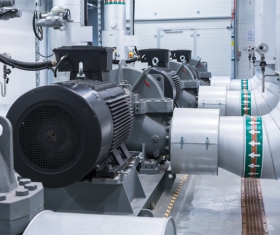

Expert Solutions You Can Trust

With over seventy years of experience, Gilbert-McEachern Electric is your trusted partner for industrial motor solutions. Our skilled team works with you to assess your current motor systems and identify opportunities for improvement. Whether you need to replace outdated motors, add modern technologies like variable frequency drives (VFDs), or choose reliable products from top-quality brands like Sprecher Motors, we provide the guidance you need to achieve lower costs and a reduced environmental impact without the hassle.

Here’s the bottom line…

Upgrading to energy-efficient motors is a smart move for any business. Not only will you see savings on your electricity bills, but you will also contribute to a healthier environment (and that’s something customers take seriously in our modern business landscape).

Contact Gilbert-McEachern Electric today to explore energy-efficient motor solutions tailored to your business. Our team is here to help!