At Gilbert-McEachern Electric we are always working to provide better products and services to our loyal customers as well as looking for opportunities to give back to the community we serve. Here is what the Gilbert-McEachern Electric team has been up to recently.

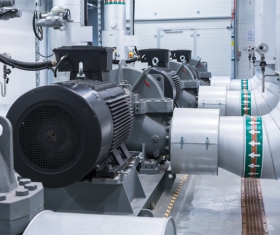

Industrial businesses, manufacturers, and facility managers are under increasing pressure to cut costs and reduce their environmental footprint. In today's competitive market, upgrading to energy-efficient motors is a practical step toward achieving both. These motors use less electricity, lower operational expenses, and help you meet new sustainability and regulatory standards. Here’s why you should make the switch:

Lower Costs and Faster Returns

Energy-efficient motors consume less electricity than older models. This reduction in energy use means lower electricity bills and quicker payback on your investment. Many businesses are choosing energy-efficient motors because they provide a faster return on investment (ROI). As a bonus, there are also many government incentives and rebates available that can help reduce the initial cost of upgrading your equipment.

Reducing Environmental Impact

Switching to energy-efficient motors not only saves money but also reduces your company’s carbon footprint. By using less energy, your business can lower greenhouse gas emissions and support sustainability goals. This is important as new regulations and environmental standards continue to emerge.

Government Incentives

There are several rebate programs and incentives available from the Government of Canada and local agencies. These programs help offset the cost of upgrading your motors, making it easier to invest in energy-efficient technology. Our team can help you navigate these options and choose the best solution for your business.

Expert Solutions You Can Trust

With over seventy years of experience, Gilbert-McEachern Electric is your trusted partner for industrial motor solutions. Our skilled team works with you to assess your current motor systems and identify opportunities for improvement. Whether you need to replace outdated motors, add modern technologies like variable frequency drives (VFDs), or choose reliable products from top-quality brands like Sprecher Motors, we provide the guidance you need to achieve lower costs and a reduced environmental impact without the hassle.

Here’s the bottom line…

Upgrading to energy-efficient motors is a smart move for any business. Not only will you see savings on your electricity bills, but you will also contribute to a healthier environment (and that’s something customers take seriously in our modern business landscape).

Contact Gilbert-McEachern Electric today to explore energy-efficient motor solutions tailored to your business. Our team is here to help!

We are quickly approaching 2025 and the world of industrial motors is evolving just as fast as many other industries. New technologies, environmental demands, and market shifts make for some exciting innovations on the horizon. Let’s look at five trends you can expect to see in 2025 in our industry around the globe… Energy efficiency is at the forefront of most markets and industrial motor development is no different. According to Future Market Insights, the global market for energy-efficient motors is set to grow significantly, projected to reach $151 billion by 2034. Stricter energy regulations and the rising costs of electricity are pushing industries to adopt motors with better efficiency ratings, such as those equipped with variable frequency drives or permanent magnet technology. These advancements aren't (just) about saving money. Think of them as part of a broader move toward reducing the carbon footprint of industrial operations—a win for businesses and the environment alike. As you can imagine, automation has steadily been transforming how motors are designed and deployed. From robotic arms on assembly lines to high-speed packaging systems, industrial robotic motors now offer unprecedented precision and speed. As noted by Straits Research, the market for industrial robotic motors is expected to grow at a CAGR of 12.22%, driven by the rise of e-commerce and the growing need for automated solutions in manufacturing. Basically, motors are becoming more intelligent and customizable. That means they can be adapted to meet the exact needs of specific robotic applications…providing better performance, reliability, and long-term cost savings. In today’s day and age, motors aren’t always just standalone components. The Industrial Internet of Things (IIoT) can connect motors to broader systems, enabling real-time monitoring, predictive maintenance, and smarter operations. ResearchAndMarkets.com highlights this shift from product-based to solution-based offerings, where digital tools complement the hardware. This integration allows businesses to track motor performance in real-time, anticipate maintenance needs, and optimize operations. For industries relying on consistent performance, digital integration is a game-changer. Think more reliability and reduced costly downtime. From aviation to intricate manufacturing processes, the demand for compact and lightweight motors is on the rise. Smaller motors that pack a punch are opening doors to applications previously thought impossible, giving businesses more flexibility in how they operate. Sustainability IS a buzzword…BUT it’s also a driving force in industrial motor applications. From hydro-powered production methods to motors designed with recyclability in mind, the entire lifecycle of motors is becoming more eco-conscious. As businesses prioritize sustainability, motors with lower environmental impact will more than likely become the standard. Trends are global, but the expertise to meet those needs is often local. At Gilbert-McEachern Electric, we specialize in solutions tailored to the unique challenges of our clients. Whether it’s upgrading to energy-efficient motors or exploring the latest advancements, our team is here to help. Contact us today to learn how we can support your business.1. Efficiency Meets Sustainability

2. Automation and Robotics

3. Digital Integration

4. Compact, Lightweight Motors for Specialized Applications

5. Sustainability-Driven Innovation

Electric motors are essential components in a wide range of applications, from industrial machinery to household appliances. When these motors experience issues, motor rewinding is an effective solution. But what exactly is motor rewinding, and how can it benefit you? At Gilbert-McEachern Electric, we specialize in providing top-tier motor rewinding services, and we're here to explain the process and its advantages.

What is Motor Rewinding?

Motor rewinding is a meticulous repair process that addresses shorted, grounded, or damaged coils within an electric motor. This involves carefully removing the damaged windings and replacing them with new ones to restore the motor to peak performance. It’s an ideal solution for motors that are underperforming or have stopped working.

Recognizing the signs that indicate your motor needs rewinding is crucial for maintaining its efficiency and avoiding complete failure. Visible deterioration, such as burns, broken parts, moisture damage, or rust, is a clear indication that rewinding is necessary. Performance issues, including noticeable drops in efficiency or motor stoppages, also signal the need for rewinding. Professionals can measure winding resistance to check for shorted coils. If the resistance levels don’t match the specifications, a rewind might be needed. Low insulation resistance, often due to contamination, vibration, or power surges, is another sign that your motor may require rewinding. Motors that are less than 12-15 years old and showing wear are good candidates for this process. The Benefits of Rewinding Your Motor Opting to rewind your motor offers several significant advantages. It is a cost-effective solution, typically costing about 40% of the price of a new motor. This makes it a budget-friendly alternative to replacement. Motor rewinding is also eco-friendly, as it reuses the motor’s existing components, reducing the environmental impact compared to manufacturing a new unit. Modern rewinding techniques can enhance a motor's efficiency, sometimes even surpassing its original performance...and rewinding can significantly extend the lifespan of your motor, delaying the need for a costly replacement. Why Choose Gilbert-McEachern Electric? At Gilbert-McEachern Electric, we pride ourselves on our comprehensive motor rewinding services. Here’s what sets us apart: -Complete Services: We offer rewinding for AC and DC motors, clutches, brakes, coils, and generators - providing voltage and frequency changes, multi-speed rewinding, special design motors, and more. -Quality Materials: We use only high-quality materials to ensure the longevity and reliability of your motor. -Variety of Services: Beyond motor rewinding, we offer electrical and mechanical repair, pump repair, part sourcing, panel building, and servo motor diagnosis and repair. -Commitment to Efficiency: Our highly trained team ensures that your equipment operates at peak efficiency. -Quick Turnaround: We emphasize prompt service, ensuring your motor is back in operation as quickly as possible. Motor rewinding is a smart, effective solution for maintaining and enhancing the performance of your equipment. By choosing Gilbert-McEachern Electric, you benefit from our expertise, quality materials, and commitment to customer satisfaction. Extend the life of your motors, save money, and contribute to a greener planet with our professional motor rewinding services. Explore our services further and see how Gilbert-McEachern Electric can help keep your motors running smoothly. We have locations in Brantford and Cambridge. Visit our website or contact us today!